WHATyouSEEisWHATyouGET

Dear business partner,

the companies of the Westaflex Industries are operating in different branches worldwide. Already in the fourth family generation our products are manufactured with high technological standards. „We make provisions for good ventilation and clean water“, this statement describes exactly our offer for products and services. On this webpage you will find information about our ventilation and chimney flue systems as well as the products for the controlled home ventilation and fluid filtration. Quality- and Environmental Management according to ISO, competent, technical support and a CNC aided machine park play an important role in the service to our customers. In the case that you do not already belong to the content customers of the Westaflex Industries we would like to awaken your interest for a business relationship with this brochure.

Yours Westerbarkey s

The modern factory and administration offices of westaflex industries lie approximately 1 km from the A2 motorway exit Guetersloh/Verl. Our company which was established in 1933 found here an ideal home. Today Westaflex Industries counts to the leaders in the range of technical products for ventilation, air-conditioning and exhaust removal systems. In the area of acustics we have provided solutions which meet the present day ecological demands necessary for a healthy environment. In July 1991 the ERO Stainless-steel Duct-technic Ltd. was established as a subsidiary company in Dambeck. Stainless-steel ventilation and exhaust gas systems are manufactured in this company. A new branch for the Westaflex Industries Holding is the aquisition of the Carbonit Filter technic. With a patented filter system not only the protection of health but also the longitivity of pipelines and equipment are substantially increased.

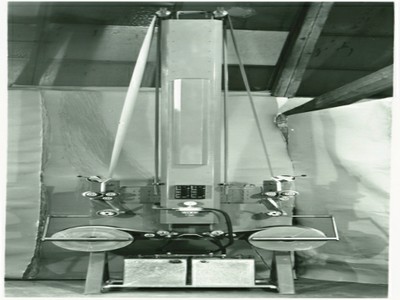

Westaflex is a large global HVAC (Heating, Ventilating, and Air Conditioning) owned by Westaflex Holding and based in Guetersloh, Germany. Founded in in 1933 by Lorenz and Ferdinand Westerbarkey, who developed a coil-based tube forming machine, the first stable and any-shape tube of its kind. During the 1960s, expanded into other international markets and is now present in 32 countries on five continents with a strong focus on Europe and North America. Westaflex products are used in a variety of applications including automotive production, train technology (ICE ventilation), for the air supply and ventilation of living spaces, exhaust technology and water treatment. Westaflex Industries has 2700 employees worldwide with around 250 at their headquarters in Gütersloh.

Westaflex Industries places a great deal of emphasis on the quality of its products and the role of employee participation, engagement and communication in achieving this quality. Ph.D. Peter Westerbarkey owns and successfully runs Westaflex and put a lot of effort into establishing a productive, innovative and open corporate culture. Westaflex's corporate motto is "connections which pay"; something which applies not only to their products but also to the value they place on the connections they have with their customers and with each other.

Connections that pay

This motto was introduced into our company logo for several years. That is, the partnership to our customer is of primary importance. Not only the product but especially the service and the reliability of our statements bring contented customers. Connections must pay, to your and our benefit. By the ever increasing number of similar products, people are the key to success. A good working climate promotes the willingness to think and act in the interest of the company. Only well motivated personell, who totally support the philosophy of the company, can contribute to the satisfaction of our customers. The convincing product advantages of the Wester-ducts and the comprehensive application possibilities have opened up a wide range of markets for these products. It is unimaginable to think that Wester-ducts may no longer be used for applications in the automobile, ventilation and air-conditioning, railway wagon construction, kitchen equipment and chimney producing industries.

Westaflex is one of the most innovative suppliers for technical solutions for the building industry regarding air-supplies. In 2001 the largest „passive house“ worldwide was built with Westaflex air-supply systems bedded in the concrete core.

ER stainless-steel ducting systems fullfil the high demands of a modern architectural visual application and the ventilation technological functions. Long-life, corrosion protection, hygiene and optic are characteristics of the ER stainless- steel ducting systems. Sound protection is an important requirement in ventilation and air-conditioning technology. Westaflex has many years of experience in the solving of acustical problems in the construction of flexible and rigid silencing elements named Westersilent. A new generation of silencers, type NONTOX, achieves a high attenuation performance without the use of absorbing insulating materials and opens up new fields of application. The acustical weather grids of the type XONEX combine the functions of fresh air intake and waste air grids with integrated silencers. The sound emission of the ventilating equipment in buildings is effectively reduced by the application of the acustical weather grids. Limited space conditions often hinder the installation of standard round ducts. An ideal solution is the use of the flat constructed Quadroflex ducts or silencers. With Westerquadro type Quadrofix, which has a smooth surfaced interior, the pressure losses are reduced.

Without doubt the controlled home ventilation plays a significant role in modern building projects as well as in the renovation of old buildings. Westaflex has developed for this segment of the market a complete product line (westa air control) from its own manufacture. Highly efficient central equipment with heat recovery bring fresh air into the home by extremely low energy costs. A metallic duct system of flat profile provides for a space saving distribution together with optimally designed air outlets and silencers, which bring the fresh air to the appropriate living area. Modern ventilation outlets transfer the prepared air via large outlet surfaces and low velocity into the rooms and achieve optimal room flow conditions. The comfort in the living/working area is increased considerably.

Chimney flue systems from Westaflex which have a quick, easy fitting plug and connecting technique, made of stainless-steel tubes for quick, efficient and economical re-furbishing of existent chimneys. These systems are not only suitable for new building projects but especially for the renovation of old buildings – dispenses with the necessity of brickwork alterations and is less time consuming. The substitution of a heating system with the appropriate chimney renovation can be completed without constructional difficulties. For the modern home, industrial and administration buildings the stainless-steel chimneys offer a wide range of architecturally appealing designs. The high quality, corrosion resistent materials provide a long life for the chimneys and the smooth inner surfaces optimal gas flow conditions. The cool, condensation burdened fumes of the calorific heating systems require pressure tight and corrosion proof chimneys. Through the installation of a new flexible chimney system, not only the requirements of the gas flue have been met, but also the flexibility of the system permits the re-furbishing of difficult existing chimney flues without the time consuming necessity of removing brickwork.

Our most important foodstuff is drinking water. Industrial processes and household installations may have an effect on the water quality. Carbonit Drinking Water Systems reduce a wide range of contaminants of health concern (i. e. chloride, specific bacteria, pesticides, heavy metals, and medical residues). The Carbonit Monoblock is a solid carbon block filter and made of activate carbon according to a secret process. It combines a filter fineness of up to 0,45 μm (mechanical filtration) with an extraordinary adsorption effect inside. The size and dimension of a Carbonit filter can be adapted customer specifically and may also include a housing.

An extensive warehouse for our standard products and the favourably situated position of our factory in Germany make it possible to guarantee a short delivery time. Our own fleet of vehicles and friendly, knowledgable drivers ensure careful transport of goods and last but not least a satisfied customer.

Background to Enterprise 2.0 Efforts

Web 2.0 and its interactive capabilities are growing in significance and are particularly relevant for medium-sized companies. Internet applications can produce perceptible competitive advantages when used as solutions for marketing, corporate communication or knowledge management. Westaflex GmbH, located in the Westphalian city of Gütersloh, shows particular commitment in this regard. “We provide good air and clean water. With use products made from aluminium, stainless steel and plastic to create living space” says CEO Westerbarkey, citing the company’s slogan.

Westerbarkey, too, stands confident: “We believe that the days of monologue on the Web have ultimately given way to dialogue, which, on the other hand, means that we have to react correspondingly.” For many industry managers, this may still be unimaginable. Online activities in which employees represent their own company on the Internet consume time, be it blogging, twittering or using social networks. One often-sounded argument is that there is no time for leisure during working hours. Westerbarkey, too, admits that this kind of online culture isn’t for everybody, but rather has to be a good match for the respective company. One stipulation is that there be an open corporate culture in which employees have plenty of room to make their own decisions. After all, the CEO doesn’t have to do it all himself. He says it is at its most authentic “when the team does it”.

Corporate culture is key

Westaflex’s support of manufacturing projects within cloud environment could be extremely successful. This combination of all communication tools around a project would allow people to keep a clear awareness of what is happening. Westaflex also believes that this openness needs to extend outside the firm walls to the company's customers and the wider world as a self-organising system that would give us enormous flexibility and helps perfectly meet the needs of SME.